While In The Shop

Auto Body Shop Blueprinting

The repair process begins by having the shop foreman handle the blueprinting of your vehicle. What is blueprinting? — Blueprinting is marking the vehicle with a water soluble marker as to what is being done to the particular part—i.e. replace fender, remove and install new molding, repair door, etc.

The vehicle is then assigned to the technician who performed the initial disassembly and evaluation of the collision damage. From there, the vehicle goes through the standard repair process.

Why Network Auto Body?

Network Auto Body is proud to be:

- Jaguar and Land Rover Authorized Aluminum Repair Center for Structural and Non-Structural Repairs

- Honda ProFirst Collision Repair Facility

- Volkswagen Certified Collision Repair Facility

- The Authorized Body Repair Facility of Mercedes Benz, Nissan, and Infiniti

Our technicians are all I-CAR certified, and our tools and equipment are tested and approved by the auto manufacturers above.

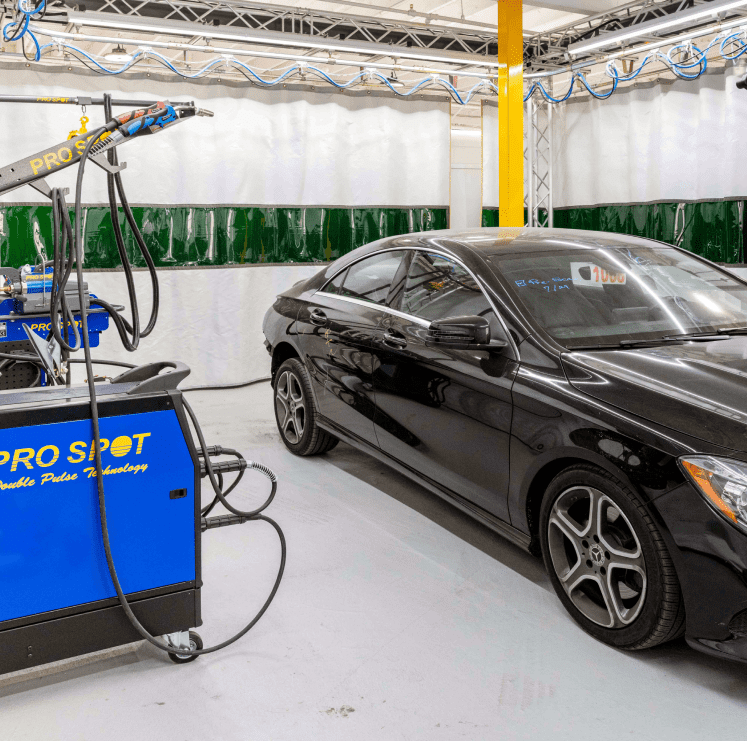

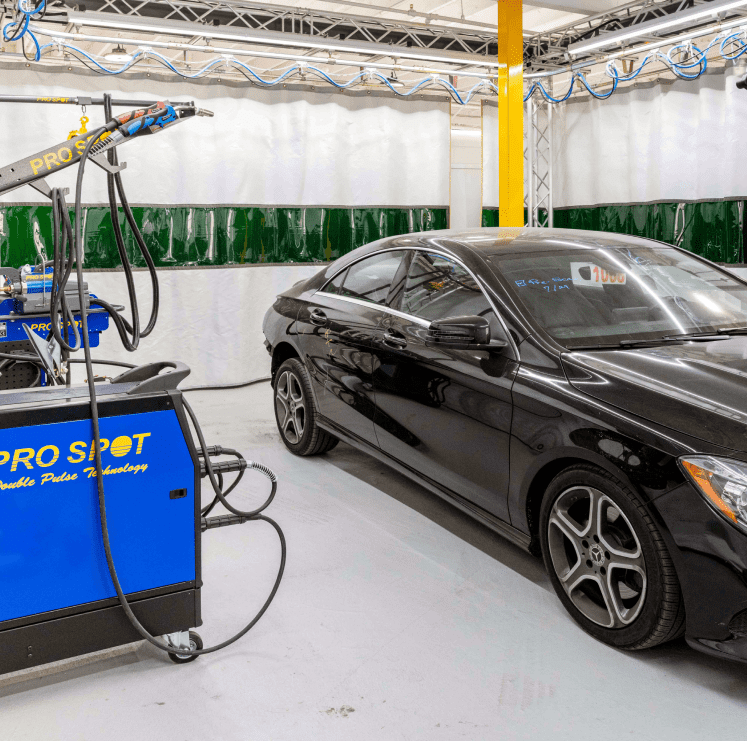

For luxury cars, which are often made with aluminum parts, our state-of-the-art Aluminum Repair Environment, known as the Clean Room, allows us to repair all aluminum vehicles. We are one of only a few Southern California body repair facilities offering this service at such a high quality.

For Land Rovers and Jaguars, we are one of the few body shops in Southern California certified to provide structural work on your vehicle. We provide quality collision repair for luxury vehicles.

Why Network Auto Body?

Network Auto Body is proud to be:

- Jaguar and Land Rover Authorized Aluminum Repair Center for Structural and Non-Structural Repairs

- Honda ProFirst Collision Repair Facility

- Volkswagen Certified Collision Repair Facility

- The Authorized Body Repair Facility of Mercedes Benz, Nissan, and Infiniti

Our technicians are all I-CAR certified, and our tools and equipment are tested and approved by the auto manufacturers above.

For luxury cars, which are often made with aluminum parts, our state-of-the-art Aluminum Repair Environment, known as the Clean Room, allows us to repair all aluminum vehicles. We are one of only five Southern California body repair facilities to offer the service.

For Land Rovers and Jaguars, we are one of the few body shops in Southern California certified to provide structural work on your vehicle. We provide quality collision repair for luxury vehicles.

The #1 Collision Repair Center In Los Angeles

Network Auto Body is proud to be the #1 collision repair center throughout Los Angeles. Our factory trained technicians are manufacturer certified and use the most advanced equipment and techniques to repair your vehicle to the highest standards.

All of our locations are equipped with Rotary Compressors that use less energy compared to conventional compressors. We also use Celette and Car-O-Liner Frame Equipment, which accurately detects the slightest deviations in your vehicle’s frame alignment that could, if uncorrected, compromise your vehicle’s structural integrity.

Our repairs are thorough and detailed, and we have one simple goal: restore your car to its original factory condition and get you back on the road as soon as possible.

Frequently Asked Questions

Exclusive Body Shop for Top Dealerships

Network Auto Body Inc. has partnered with passionate dealers who are not only experts in their market but who also share our vision of nurturing a purposeful way of doing business.